Company History

Bringing SMRs to Market

Since our founding in 2007, we have made significant progress towards commercializing America’s first small modular reactor (SMR). Our NuScale Power Module™ is the only SMR on the market that:

- is approved by the U.S. Nuclear Regulatory Commission

- is part of a completed standard plant design

- is ready to deploy worldwide

- has begun factory production for first modules

- has completed the R&D phase

See Our Progress

![E2 Center room at Ohio State University.]()

2024

- Opened an Energy Exploration (E2) Center at The Ohio State University in Columbus, OH.

- RoPower initiated the advancement of the Phase 2 Front-End Engineering and Design (FEED) study for the Doicești SMR power plant in Romania.

![Doosan manufacturing forgings for the NuScale Power Modules.]()

2023

- Doosan Enerbility begins production forgings for first NuScale Power Modules™

- The U.S. Nuclear Regulatory Commission (NRC) accepted a second Standard Design Approval (SDA) application for a 6-module power plant configuration powered by an uprated 250 MWt (77 MWe) SMR design.

- Standard Power chose NuScale as its technology provider for two SMR plants that will power data centers located in Ohio and Pennsylvania.

- Opened the first two international Energy Exploration (E2) Centers at Seoul National University and University Politehnica of Bucharest.

- Completed Phase 1 of Front-End Engineering and Design (FEED) work for the RoPower SMR plant in Romania.

- Along with Utah Associated Municipal Power Systems (UAMPS), mutually terminated the Carbon Free Power Project (CFPP) due to low customer subscriptions.

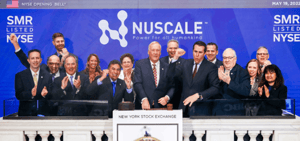

- Hosted our first Analyst Day at the New York Stock Exchange.

![NuScale team ringing the NYSE opening bell.]()

2022

- Merged with Spring Valley Acquisition Corp. to create the world’s first and only publicly traded provider of SMR technology.

- RoPower named second committed customer.

- Our Emergency Planning Zone boundary methodology is validated by the U.S. Nuclear Regulatory Commission Advisory Committee on Reactor Safeguards.

- Merged with Spring Valley Acquisition Corp. to create the world’s first and only publicly traded provider of SMR technology.

- RoPower named second committed customer.

- Our Emergency Planning Zone boundary methodology is validated by the U.S. Nuclear Regulatory Commission Advisory Committee on Reactor Safeguards.

![NuScale and JGC signing ceremony.]()

2021

- Worked with Guggenheim Securities to secure nearly $200 million in investments from GS Energy, Doosan Heavy Industries and Construction, IHI Corporation, Samsung C&T Corporation, Sargent & Lundy, Sarens, and JGC Holdings Corporation.

- Opened Energy Exploration (E2) Centers in collaboration with the University of Idaho and Texas A&M University.

- Partnered with BWXT Canada to build out the Canadian supply chain and advance manufacturing work in preparation for NuScale Power Module™ (NPM) fabrication.

- Signed Memorandums of Understanding (MOUs) with Prodigy Clean Energy, Kozloduy Nuclear Power Plant – New Build Plc (KNPP-NB), Energoatom, Nuclearelectrica, Xcel Energy, and Grant County Public Utility District (Grant PUD) to explore the deployment of SMR plants around the world.

- Signed MOUs with Getka Group, UNIMOT S.A., KGHM Polska Miedź S.A., and Piela Business Engineering to explore plant deployment in Poland.

- Working with Utah Associated Municipal Power Systems (UAMPS), we executed agreements to prepare a Combined License Application for the Carbon Free Power Project with support from a $1.355 billion multi-year DOE grant.

![Man working at NuScale E2 center.]()

2020

- Made history as the first ever SMR to receive design approval from the U.S. Nuclear Regulatory Commission (NRC).

- Using advanced testing and modeling tools, our engineers concluded that each NuScale Power Module™ (NPM) can generate 25 percent more power for a total of 77 MWe per module.

- The first Energy Exploration (E2) Center opened at Oregon State University (OSU) with support from a 2019 DOE grant.

- Signed a Memorandum of Understanding (MOU) with Ukraine’s State Scientific and Technical Center for Nuclear and Radiation Safety to evaluate regulatory and design processes associated with the deployment of SMR technology in Ukraine.

- Sarens USA provided a cash investment and agreed to provide lifting and transport services to support the deployment of our SMR technology.

- Submitted the Phase 1 and 2 combined pre-licensing vendor design review to the Canadian Nuclear Safety Commission (CNSC).

- DOE provided a sole-source award with a share of $263 million that will complete the NuScale design.

![NuScale and Doosan signing ceremony.]()

2019

- Signed Memorandums of Understanding (MOUs) to share technical expertise and explore potential SMRs as a long-term energy option for the Jordan Atomic Energy Commission, ČEZ, and Societatea Nationala Nuclearelectrica SA (SNN SA).

- Along with our partner universities, we won DOE grants for educational SMR simulators at Oregon State University, Texas A&M University-College Station, and the University of Idaho.

- Doosan Heavy Industries and Construction (DHIC) and Sargent & Lundy became new strategic partners and investors with $44 million in total investments.

- We committed to the Equal by 30 initiative in a push for gender equity.

- Our SMR design cleared Phases 2, 3, and 4 of the Nuclear Regulatory Commission’s (NRC) review process.

- We received the N Certificate of Authorization (N-Stamp), considered the hallmark of quality, from the American Society of Mechanical Engineers.

2018

- The Nuclear Regulatory Commission (NRC) concluded that the application of our novel safety design approach eliminates the need for class 1E power, the regulatory standard set for the design of safety-related nuclear power plant electrical systems.

- The NRC completed the first phase of the design certification application (DCA) review.

- We received $40 million in cost-sharing financial assistance from the DOE under its “U.S. Industry Opportunities for Advanced Nuclear Technology Development” funding opportunity.

- The DOE additionally awarded us $7 million under a First of a Kind (FOAK) Nuclear Demonstration Readiness Project pathway.

- We signed Memorandums of Understanding (MOUs) with Ontario Power Generation and Bruce Power to support the deployment and commercialization of our SMR technology in Canada.

2017

- The Nuclear Regulatory Commission (NRC) accepted our SMR design certification application (DCA) for review.

- The Center for Advanced Nuclear Manufacturing (CANM), operated by the former Concurrent Technologies Corporation (CTC), signed an initial contract for helical coil steam generator prototype work.

- Ultra Electronics successfully conducted the acceptance testing of the NuScale Power Module™ (NPM) protection system.

2016

- We submitted the first-ever SMR design certification application (DCA) to the Nuclear Regulatory Commission (NRC).

- We launched our fabrication partner selection process for the NuScale Power Module™ with an event in Atlanta, Georgia.

- We partnered with Sheffield Forgemasters International Ltd. to develop the manufacturing techniques required for the future deployment of SMRs in the United Kingdom.

2015

- A full-length helical coil steam generator was tested at the SIET facilities in Italy.

- Framatome (formerly AREVA) agreed to design, test, and manufacture fuel assemblies.

- We completed fabrication and assembly of a full-scale, upper module mockup of the NuScale Power Module™ (NPM).

- The NuScale Exposition (NuEx) attracted 230 attendees to Corvallis, Oregon where speakers and facility tours showcased our technology.

- We partnered with Ultra Electronics to bring their expertise in reactor protection system design, nucleonics instrumentation, nuclear qualified sensors and associated in-core, specialty cabling to our design team and support the deployment of our SMR technology.

2014

- We partnered with Enercon Services Inc. to support the development of the Design Certification Application (DCA) and deployment of our SMR technology.

2013

- We were selected by DOE to receive up to $226M of matching funds to further develop our SMR design and secure a design certification from the Nuclear Regulatory Commission (NRC).

- The Western Initiative for Nuclear (Program WIN) launched to study the deployment of our SMR technology across the western U.S., beginning with the Carbon Free Power Project (CFPP).

2012

- The world’s first SMR control room simulator was commissioned at our main engineering offices in Corvallis, Oregon to model the operation of 12 NuScale Power Modules™.

- We formed a Technical Advisory Board (TAB) consisting of highly regarded experts in nuclear plant design, operations, maintenance, regulations, and safety.

2011

- Fluor Corporation became our primary investor with funds in excess of $30 million. We also partnered with Fluor to leverage its global engineering, fabrication, procurement, and construction capabilities to support the commercialization of our SMR design.

2008

- We notified the Nuclear Regulatory Commission (NRC) of our intent to pursue a design certification for our SMR technology.

- We formed the NuScale Advisory Board (NuAB) to guide our path towards commercialization.

2007

- NuScale Power, LLC is founded and Oregon State University granted the new company exclusive rights to the SMR technology.

2003

- The DOE-funded program ended and the Oregon State University team, led by Dr. José N. Reyes, decided to build a one-third scale electrically heated version of an SMR as a test facility.

2002

- The DOE funded research led by the Idaho National Laboratory, in collaboration with Oregon State University, for the development of an SMR that could be used for multiple applications.

.png?width=300&name=e2-center%20(1).png)